Food processing is the transformation of raw ingredients, by physical or chemical means into food, or of food into other forms. Food processing combines raw food ingredients to produce marketable food products that can be easily prepared and served by the consumer.

Common food processing techniques that used in many food related industry are

- Removal of unwanted outer layers, such as potato peeling or the skinning of peaches

- Brine mixing & storage equipment

- Chopping or slicing e.g. diced carrots.

- Mincing and macerating

- Liquefaction, such as to produce fruit juice

- Fermentation e.g. in beer breweries

- Emulsification

- Cooking, such as boiling, broiling, frying, steaming or grilling

- Deep frying

- Baking

- Mixing

- Addition of gas such as air entrainment for bread or gasification of soft drinks

- Proofing

- Spray drying

- Pasteurisation

When designing solution to our client (food industry), we typically consider some performance parameters:

- Hygiene, e.g. measured by number of micro-organisms per ml of finished product

- Energy consumption, measured e.g. by “ton of steam per ton of sugar produced”

- Minimization of waste, measured e.g. by “percentage of peeling loss during the peeling of potatoes’

- Labour used, measured e.g. by “number of working hours per ton of finished product”

- Minimisation of cleaning stops measured e.g. by “number of hours between cleaning stops”

Our solutions for Food Processing Industry

Depositors

Aasted Depositor

Depositors are machines that deposit a fixed amount of product. For example, depositors are used for sandwich filling and biscuits or cookies. Volumetric depositors are also available Suitable for large range of products salad dressings, salsas, heavy sauces, ketchup, mayonnaise, mustard, tomato paste, potato salad, honey, syrup, marmalade, etc. Also suitable for non food products such as shampoos, gels, creams, etc..

Our partners for depositor machine solution

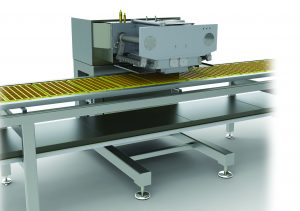

Extruding Machines

Gea Comas Co-Extrusion

There is a clear trend towards more complex products, with improved shape and color definition to provide differentiation in a crowded market. Companies competing in this sector also need equipment with the flexibility to produce a range of products that match the latest trends in consumer preference; an inbuilt ability to bring new products to market quickly; and move easily into adjacent market niches. Twin-screw extrusion is a process that connects all these requirements, and a new co-extrusion system can be added to an existing single or twin-screw extrusion line supplied by virtually any manufacturer.

The co-extrusion system provides the means of incorporating fillings with contrasting textures and colours into a cereal outer.

It provides a capacity for making added-value products with out of the ordinary shapes that catch the eye, complemented by exotic flavours and fillings.

Fillings can be of virtually any colour or flavour – creams, fruit pastes, and chocolate praline are typical.

Exotic flavours, plus glazings, frostings or chocolate coating, add even more appeal.

Extruders can be single screw or twin screw machines. In the bakery sector, multi-lane extruding and sheeting is used.

Our partners for extruding machine solution