Chocolate production process starts when cocoa beans have reached the machinery of chocolate factories, they are ready to be refined into chocolate. Generally, manufacturing processes differ slightly due to the different species of cocoa trees, but most factories use similar machines to break down the cocoa beans into cocoa butter and chocolate (International Cocoa Organization, 1998). Firstly, fermented and dried cocoa beans will be refined to a roasted nib by winnowing and roasting. Then, they will be heated and will melt into chocolate liquor. Lastly, manufacturers blend chocolate liquor with sugar and milk to add flavour. After the blending process, the liquid chocolate will be stored or delivered to the molding factory in tanks and will be poured into moulds for sale. Finally, wrapping and packaging machines will pack the chocolates and then they will be ready to transport.

Our solution for chocolate production

Aasted Moulding Lines

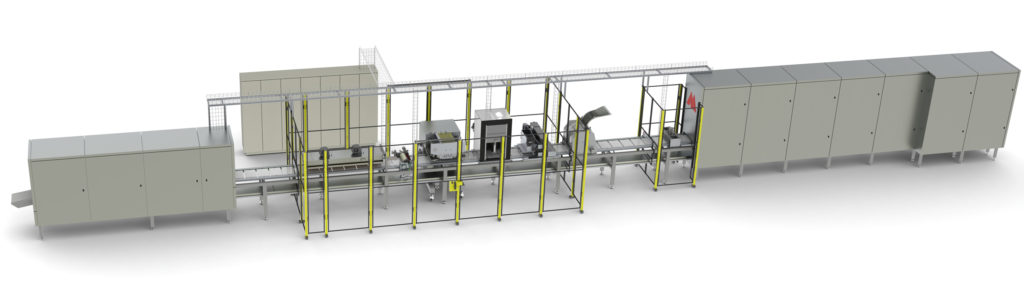

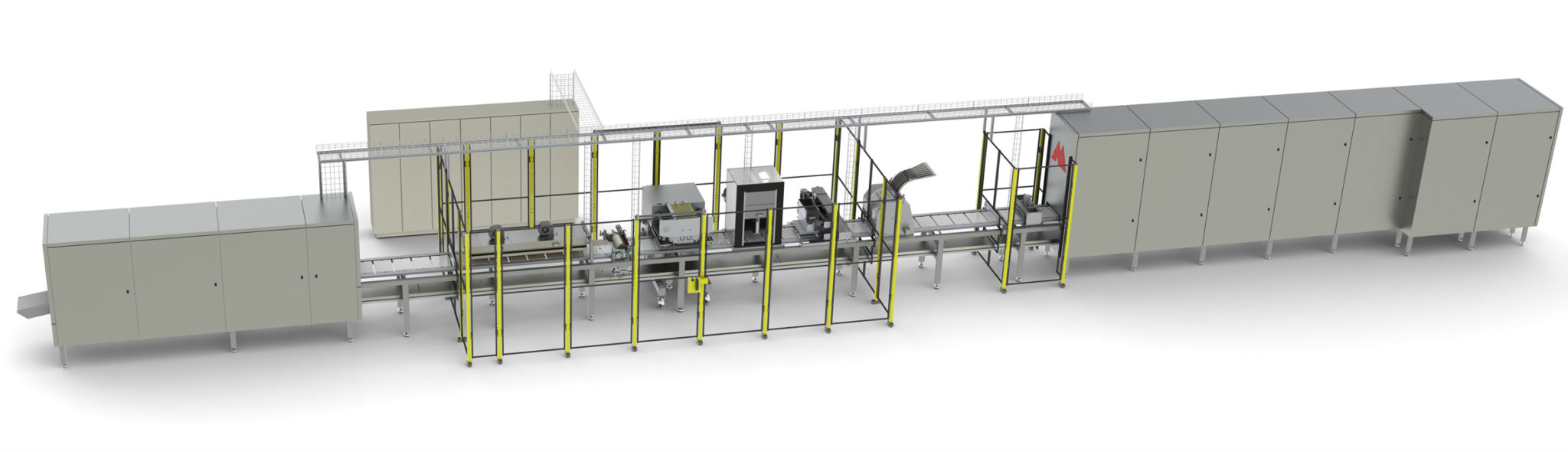

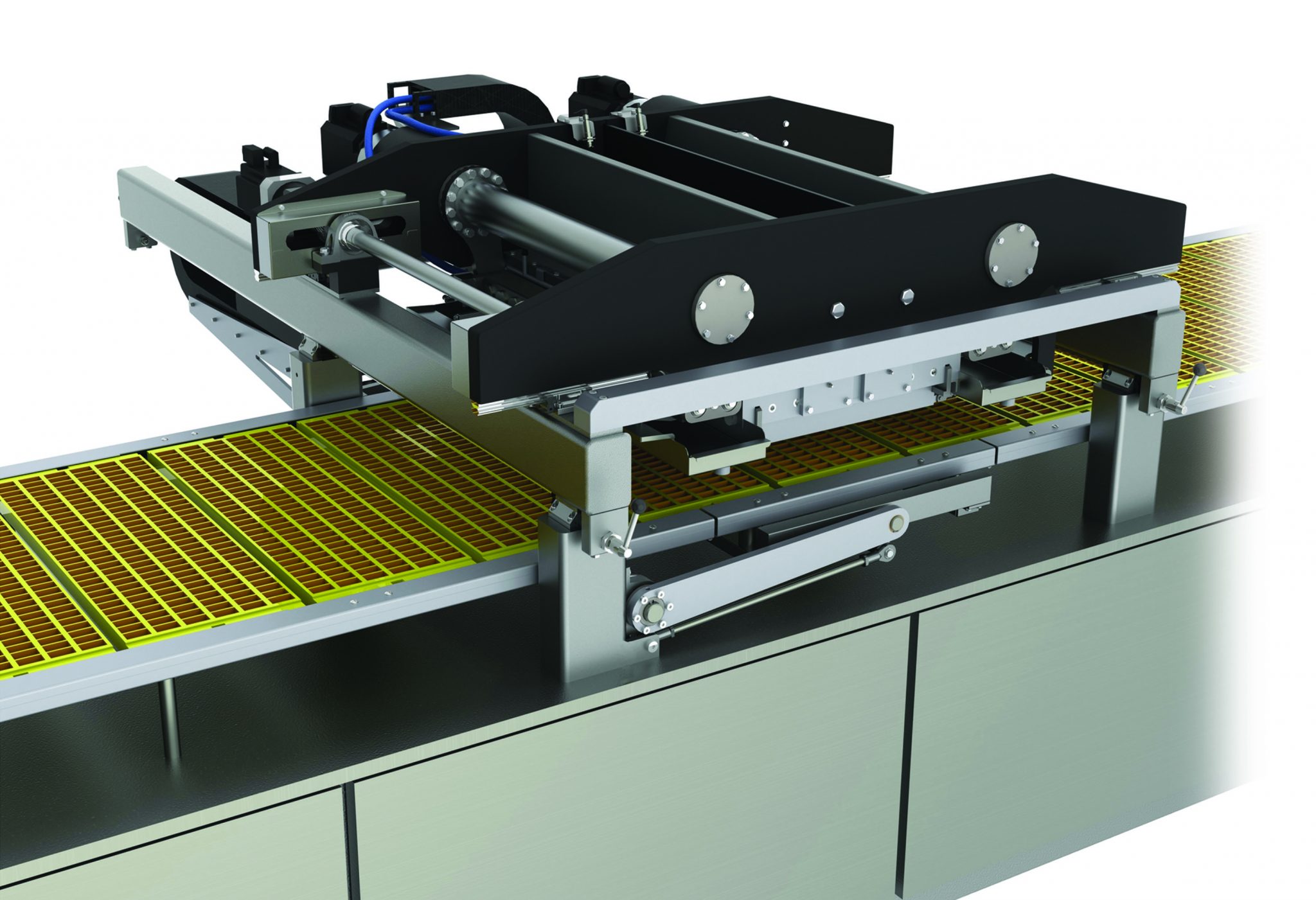

The Aasted universal moulding lines are characterized by being a long lasting, safe and profitable investment for you when the target is high volume fully automated quality chocolate moulding. Our universal moulding lines always include the newest process technology in combination with our long experience in design, manufacturing and operation of these. These lines are producing all types of moulded products such as chocolate pralines, tablets and centre filled articles. Further book moulded products are easily made on this moulding line concept. The Aasted Moulding Lines are continuously improved in terms of high efficiency, hygienic operation and easy maintenance.

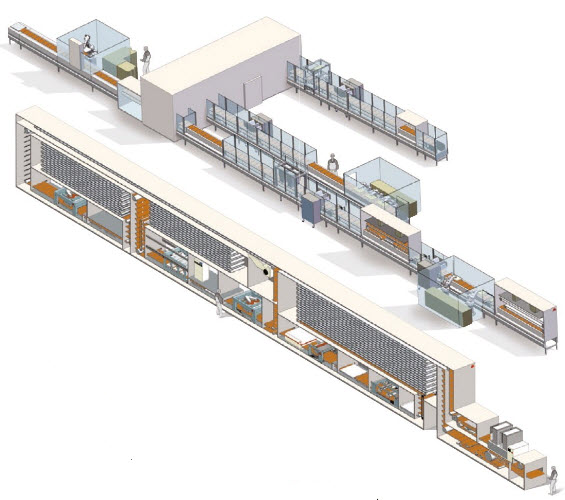

Belt Lines

The Aasted Belt lines are fully automatic production lines for chocolate, compound, chips, sticks, bottoms and kippels. The lines require only a minimum of attendance. Made for 24/7 operation the hygienic design gives the Aasted belt lines a constantly high efficiency rate. The lines are built up in modules easily tailor made to fit your specific demands.The lines are fully tested before shipment and since the belt lines are built up in modules the installation time is short.

Tempering Machines

Moulding Lines

Enrobers

Depositors

Cooling Tunnels

-

Tempering Machines

The SuperNova Energy tempering series is the 21st century's solution to chocolate tempering. 65 years after Dr. K. Aasted invented the world's first continuous chocolate plate temper, Aasted remains a market leader for chocolate production solutions. -

Moulding Lines

The Aasted universal moulding lines are characterized by being a long lasting, safe and profitable investment for you when the target is high volume fully automated quality chocolate moulding. Our universal moulding lines always include the newest process technology in combination with our long experience in design, manufacturing and operation of these. -

Enrobers

Since 1942, Aasted has worked to create a collection of world-class enrobers through innovative thinking and cross-collaboration. Our Nielsen enrober series will provide you with advanced technology solutions. -

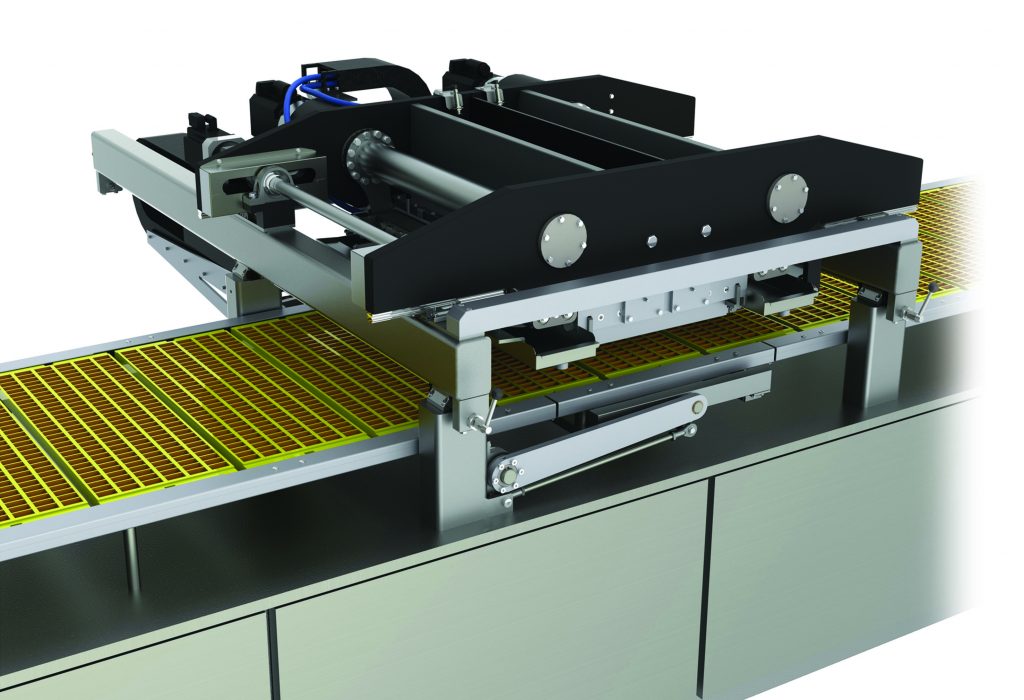

Depositors

For the last 90 years Aasted has manufactured world class depositors to customers around the world. We have a large portfolio of depositing machines that are highly efficient, and known to minimize production time. -

Cooling Tunnels

The Nielsen Cooling Tunnel series is designed to provide radiant, direct, and indirect cooling. Available width lengths range from 420-2500mm. The sleek and hygienic Scandinavian design of the tunnels will truly add production quality to your lines.